Laser Engraving Acrylic

At Laser Alliance, acrylic cutting and engraving are among our most requested services.

If you’re exploring work in other materials such as wood, visit our laser cut wood or learn more about our laser engraving wood

For more information on our equipment capabilities, view our full laser cutting capabilities

If you’re ready to begin your acrylic laser engraving project, request a quote through our Quote Request”

We work with a wide range of acrylic thicknesses and provide high-precision laser cutting and engraving for everything from prototypes to custom signage and specialty products.

Laser Alliance delivers premium laser engraving acrylic services for customers across San Jose, Milpitas, and the entire Bay Area since 1999 – helping you turn ordinary piece of acrylic into stunning, high-impact pieces.

Using advanced CO2 laser technology, we create crisp, frosted markings by precisely etching the surface of the acrylic.

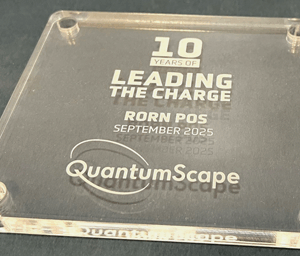

The result: clean, professional designs that never fade, peel, or wear off.

For cylindrical items like bottles, our rotary engraving system keeps the piece rotating during the process, ensuring sharp, perfectly even engraving around the entire surface.

Popular Uses for Laser Engraved Acrylic:

- Customized gifts that leave a lasting impression (drinkware, photo frames, keepsakes)

- Elegant architectural accents (windows, partitions, mirrors)

- Professional corporate branding and logos

- Awards and promotional items that stand out

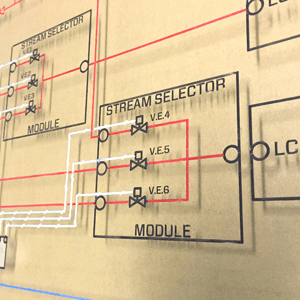

- Permanent serial numbers and part identification

- Durable barcodes for inventory and compliance

- Medical device marking

- Automotive engraving plaques

Whether you need a single personalized gift or large-scale commercial marking, laser-engraved acrylic adds elegance, durability, and premium value to any product. Let Laser Alliance bring your ideas to life with precision, consistency, and craftsmanship you can trust.